In 1917, Albert Einstein distributed the primary paper perceiving the science behind lasers. Following a long time of innovative work, Theodore Maiman showed the leading working laser at Hughes Research Laboratories in 1960. By 1967, lasers were being utilized to penetrate precious stone passes on and cut metals. Laser power offers to make its utilization regular in present-day production.

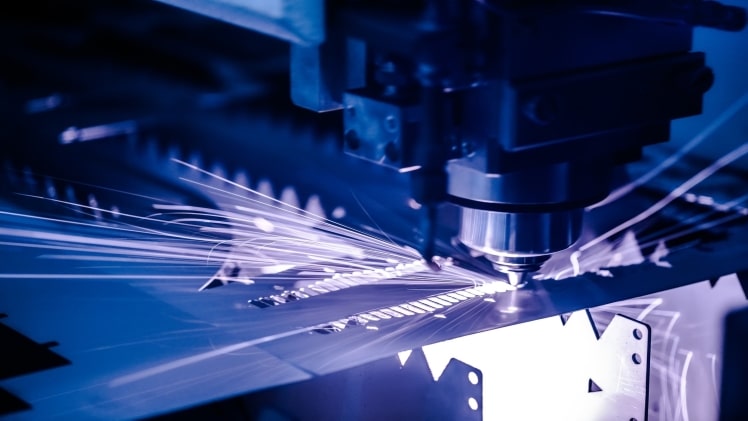

Lasers are utilized to cut materials other than metals, and laser cutting has turned into a significant piece of the advanced sheet metal shop. Before the innovation was accessible, most shops depended on shearing and punching to make workpieces from level materials. You can click this link to find laser metal cutting machine for sale.

Shears come in a few styles, yet all make single, straight cuts, requiring different arrangements to make a section. Whenever bent shapes or openings are required, shearing isn’t a choice.

Punching is the activity of decision when a shear can’t be utilized. Standard punches come in different round and rectilinear shapes, and when the ideal shape is nonstandard, specials can be made. For complex shapes, a CNC turret punch would be utilized. The turret holds one or two sorts of punches that give the ideal shape when joined in the grouping.

Not at all like shearing, laser cutters can create any ideal shape in a solitary arrangement. Programming an advanced laser shaper is somewhat more troublesome than utilizing a printer. Laser cutters wipe out the requirement for devoted devices like exceptional punches. Eliminating exceptional apparatuses diminishes lead times, inventories, improvement costs, and the gamble of old tooling. Laser reducing additionally disposes of the expenses related to honing and supplanting punches and keeping up with the front line of shear.

Laser cutting is a noncontact action, too, in contrast to shearing and punching. Powers created during shearing and punching cause burrs and part twisting, which should be treated with auxiliary tasks. Laser cutting doesn’t make a difference any power to the unrefined components, and ordinarily, laser-cut parts don’t need deburring.

Other adaptable warm cutting strategies like plasma and oxyfuel are accessible, and they are, for the most part, less expensive than laser cutters. Nonetheless, in all warm cutting activities, there is a hotness impacted zone, or HAZ, in which the compound and mechanical properties of the metal have changed. The HAZ can debilitate materials and cause different activities, like welding. When contrasted and the other warm-cut advancements, laser-cut parts have a small HAZ and lessen or dispose of the auxiliary activities expected to treat it.

Lasers are great for cutting as well as joining. Laser welding offers many benefits rather than more traditional welding processes.

Similarly, as with cutting, welding makes a HAZ. Controlling its size, shape, and properties is an unquestionable requirement while making welds on essential parts like those found in gas turbines or aviation parts. Like laser cutting, laser welding has a tiny HAZ, giving a particular benefit contrasted and other welding advancements.

The closest contender to laser welding, latent tungsten gas, or TIG welding, utilizes a tungsten anode to make an electric bend that softens the welded metal. The outrageous circumstances found around the circular segment make the tungsten disintegrate over the long run, bringing about fluctuating weld quality. Laser welding isn’t dependent upon anode wear, so the weld quality is more predictable and simpler to control. Laser welding is the best option for essential parts and challenging to-weld materials because the interaction is robust and repeatable.

Modern utilization of lasers isn’t restricted to cutting and welding. Lasers are utilized to make tiny parts with a calculation of a couple of micrometers in size. Laser removal is utilized to eliminate rust, paint, and different things from the outer layer of parts and get ready parts for painting. Part stamping with lasers is eco-accommodating (with no synthetics), quick, and highly durable. Laser innovation is extraordinarily flexible.